Marine Equipment

In order to use electrical or electronic equipment in a marine environment, it is necessary that they have additional protection to prevent oxidation and corrosion of the components.

Terasaki switches, thanks to their certification for marine use, are designed to withstand marine environments, even when installed on the coast, which, thanks to the treatments applied as well as the materials used in their construction, ensure operation and/or replacement and parts for at least 25 years. Standard switches for industrial use (offered by our competitors) are not recommended for marine applications, because their main contacts will produce rust on their terminals, and in the case of electronic switches, the integrated circuits (resistors, diodes, capacitors, etc.) are very prone to oxidation, increasing the risk of failure in the operation and activation of each of the protections.

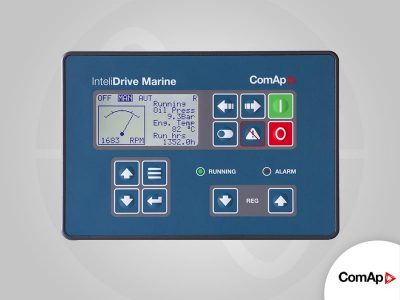

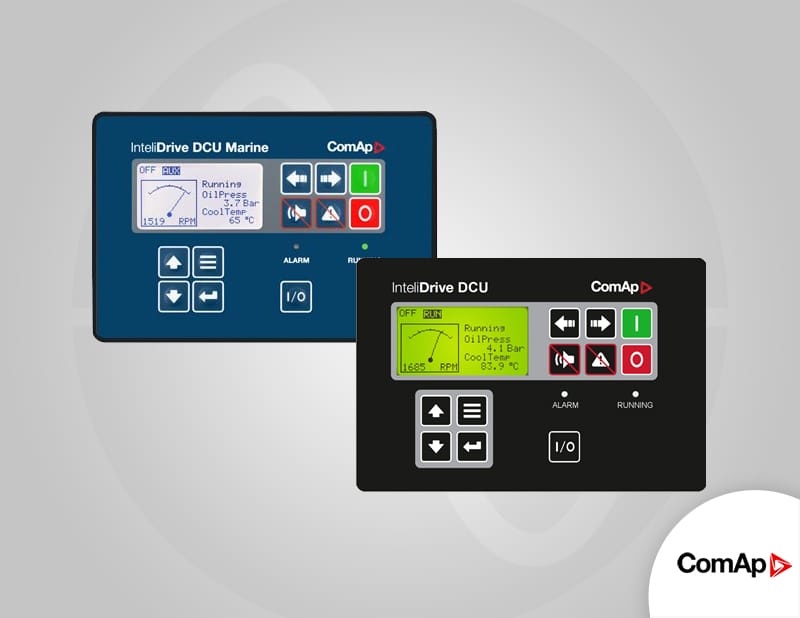

In the case of ComAp controllers for marine use, protection is applied to all integrated with dielectric varnish, to prevent corrosion appears by the high relative humidity and salinity in the environment that cause irreparable damage to the controllers.

That is why TERASAKI switches and COMAP controllers have been tested to meet the highest standards to withstand the hostile marine environment. These standards ensure that the equipment can withstand:

- High temperatures: very common in a vessel's engine room.

- Terasaki circuit breakers: Terasaki equipment can operate at extreme temperatures up to 65°C and their trip curves are calibrated at 50°C (those of a common circuit breaker barely withstand 40°C and at higher temperatures they trip suddenly without any overload or short circuit).

- ComAp controllers: designed to work at temperatures up to 70°C, and with IP65 protection, which makes them resistant to water splashes and any other liquid present on a vessel.

- Vibration: produced by strong sea currents when a vessel is at sea or even by the impact of a torpedo on the vessel's hull.

- Terasaki switches: tested to remain in the "closed" position and operate at +/-1mm amplitudes of 2-13Hz and 13.2-100 Hz at 0.7g acceleration.

- ComAp controllers: ComAp marine controllers are designed to withstand vibrations of +/-1.6mm at 5-25 Hz and 25-100 Hz at 4g acceleration, as well as impacts with accelerations of 200 m/s2, which ensures engine operation even when a storm is present at sea.

- Humidity: characteristic factor of the ocean that accelerates the degradation of equipment.

- Terasaki switches: Terasaki switches, thanks to their certification for marine use, are designed to last, even when installed on the coast, which, thanks to the treatments applied and the materials used in their construction, can work at relative humidities of up to 95%.

- ComAp controllers: ComAp controllers, especially those certified for marine use, are tested to withstand relative humidity up to 95%.

The good operation of a vessel depends largely on the electrical system and the reliability of its thrusters and generators. That is why it is necessary that the switches and controllers have certifications for marine use. ComAp and Terasaki equipment are certified by the most important entities in the marine sector:

- ABS: American Bureau of Shipping, USA.

- Lloyds Register, UK.

- Bureau Veritas, France.

- Rina, Italy.

- GL-DNV: Germanischer Lloyd- Det Norske Veritas, Germany-Norway.

- Nipon Kaiji Kyokai, Japan.

- CCC: China Classification Society, China

We recommend the use of this equipment on all vessels to ensure functionality and operation at all times.